|

Material

|

Washi paper

|

|

Adhesive

|

Rubber adhesive

|

|

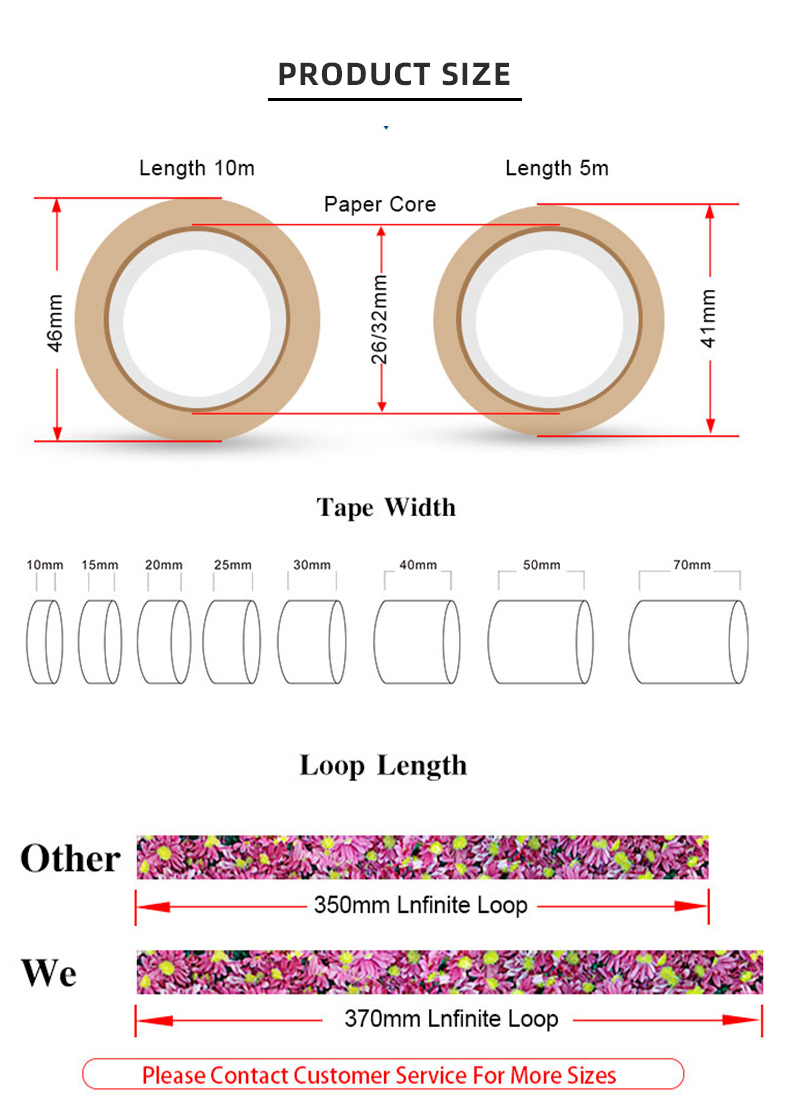

Size

|

Any size

|

|

Color

|

Any color

|

|

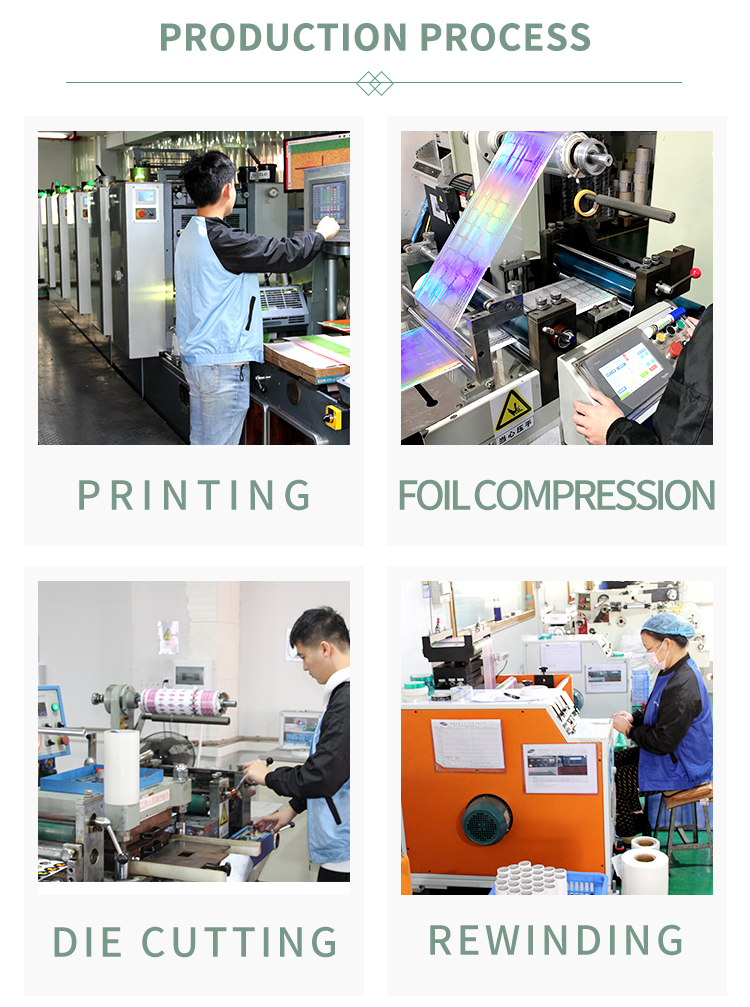

Technology

|

CMYK / Gold foil / Silver foil / Holographic / Glitter / Stamp / Overlap / Clear foil / Hollow / Glow / Sticker / Label

|

|

MOQ

|

MOQ 200 rolls for washi tape custom designs;

No MOQ for our current designs and various items can be mixed.

|

|

Package

|

OPP bag package / hot shrink wrap / craft paper box / can be customized

|

|

OEM service

|

Size,color,design,package can be customizable

|

Tips for choosing printing tape:

Printing tape is something we usually use, but there are many types of printing tape today. How should we choose when we buy it? There are two goals to understand when choosing tape:

- The characteristics of the tape: (stickiness, temperature resistance, persistence, residual glue, data quality star, curling signs, masking results, tensile strength, length, stiffness, color, weather resistance, solvent resistance , Lubrication level, dimensional accuracy, tin infiltration degree <normal, cohesion).

- Application scope: (electronics, decoration, automobile, industrial packaging, dressing, circuit board, electrical insulation, ordinary industry covering).

The commonly used tape products for electronic component packaging are as follows:

- Masking tape

Features: Excellent viscosity, good temperature resistance, good tensile strength, good persistence, no residual glue, and can stop repeated baking at low temperatures

Application: It is widely used in the manufacturing process of electronic components such as ceramic capacitors, polyester capacitors, metallized capacitors, thermistors and other products.

- Cold-pressed tape

Features: The initial adhesion is very small, the printing tape glue has excellent adhesion and cohesion, good paper quality, no curling, good masking results, and does not damage the outer film layer of the core!

Application: It is used to cover the metallized capacitor by spraying gold.

- Hot melt tape

Features: The initial adhesion is small, and it immediately exhibits excellent adhesion under heating. It is used separately from the paper tape carrier. It has good firmness, strong durability, good weather resistance, and good solvent resistance.

Application: It is widely used in the taping of waste electronic components.

- Tear the tape

Features: The initial adhesion of the tear tape is small, and the two glues face up to the bond when used, and the tape is easy to remove. The tensile strength is very good. There will be no signs of breakage. The 6000M tear tape greatly improves your productivity.

Application: Used for the taping of resistance.

- Braid tape

Features: The printing tape has good adhesion, good tensile strength, good persistence, average entanglement, length expertise, can save the frequency of loading, and improve production compliance.

Application: Adhesive tape and paper tape are used together for secondary braiding of resistors and active plug-ins.

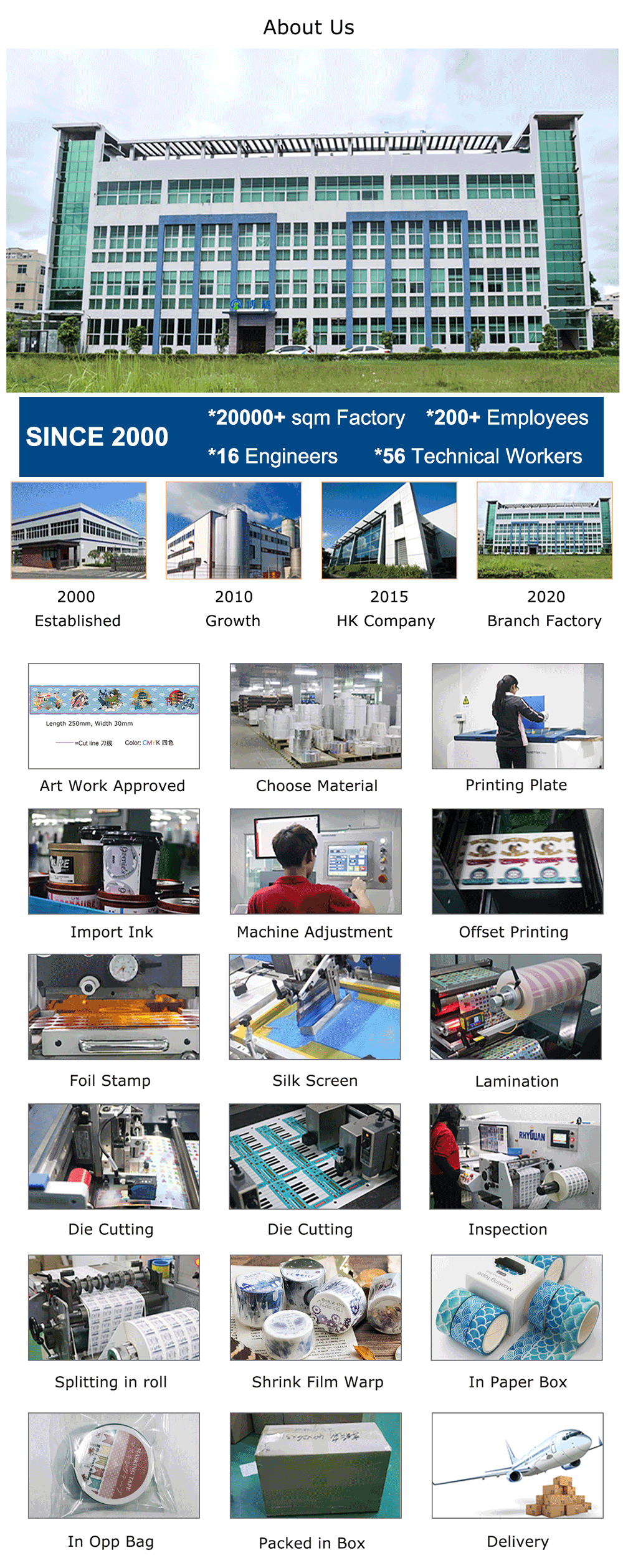

Factory warehouse: