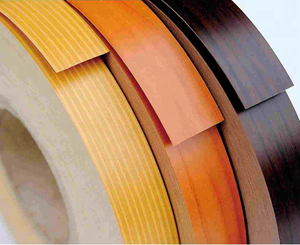

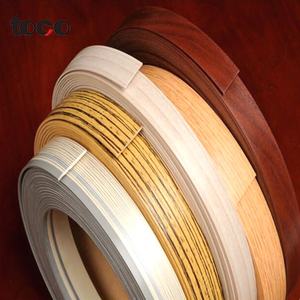

What is edge banding tape?

Edge banding glue, in fact, is also called beauty glue and edge finishing glue. It is made of new water-based epoxy resin material, with mellow luster and odorless.

Features of edge banding glue

It is mainly used to replace the traditional glass glue. The edge banding glue also has good sealing and adhesion, which can solve the defect that the glass glue is easy to black and fall off. The edge banding has rich colors, can well decorate the home, and has better flexibility, is not easy to break, and is widely used. It is one of the important auxiliary materials for fashionable home decoration.

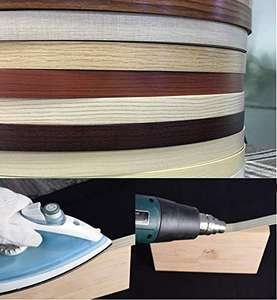

How to use edge banding?

1. Wooden edge banding

It is mainly suitable for the pasting and decoration of the edges of solid wood furniture panels, and it can only be done by hand pasting in operation. The glue for sticking the wooden edge banding is a water-soluble glue or a strong glue. When sticking, it only needs to be flat on the edge of the board, and there is no specific requirement on the ambient temperature. Because wood is a hygroscopic material, its moisture content will be affected by the external temperature and humidity. Therefore, the choice of glue should be determined according to the seasonal changes and the requirements of moisture diffusion and penetration. Only by mastering the choice of the glue type, can the edge banding and the board form a good “rivet fixing effect” through the penetration of wood fibers. In addition, furniture decorated with wooden edge banding must be painted with surface paint.

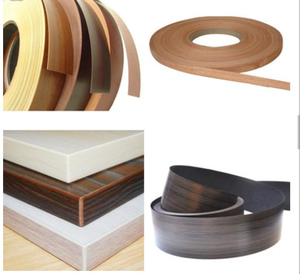

2. PVC edge banding

It is mainly suitable for edge sealing of micro riser, density board, blockboard, plywood, and solid wood edge sealing. It can be done by hand sticking and mechanical sticking when it is practical, but mechanical sticking is the main method, which can improve work efficiency. Adhesives for sticking PVC edge banding are universal glue, hot melt glue and white latex, but hot melt glue is better. During the pasting, the PVC edge bands are firmly adhered to the surface of the wood board through the action of mechanical interlocking, physical attraction, and chemical bonds. Therefore, the flatness of the substrate edge is very high when pasting, and the general tolerance should not be greater than 0.1mm. The temperature and the ambient temperature of the pasting work should be 18℃. The curing time of hot melt adhesive is generally 30 minutes, but the choice of low temperature adhesive or high temperature adhesive depends on the thickness of the edge banding strip.

3. Melamine edge banding

The scope of application is basically similar to that of PVC edge banding. But it is best to seal the edge of the fireproof board. Manual or mechanical edge sealing is acceptable in the operation; the requirements for hot melt adhesive, universal glue, white latex and other adhesives are not high; flat and rolling adhesives can be used in the market to choose adhesives; hot melt adhesives are used as glue For the mixture, the control temperature of the melt is 120℃~160℃, the pressure is 4-6/2, the curing time is 20-50 seconds, and the ambient temperature for indoor pasting is 15℃. In view of the fact that melamine edge banding has stronger permeability to hot melt adhesive and universal adhesive than PVC, the amount of glue coating should be reduced when pasting with the board, and it is generally controlled within the range of 6-8g/linear meter.